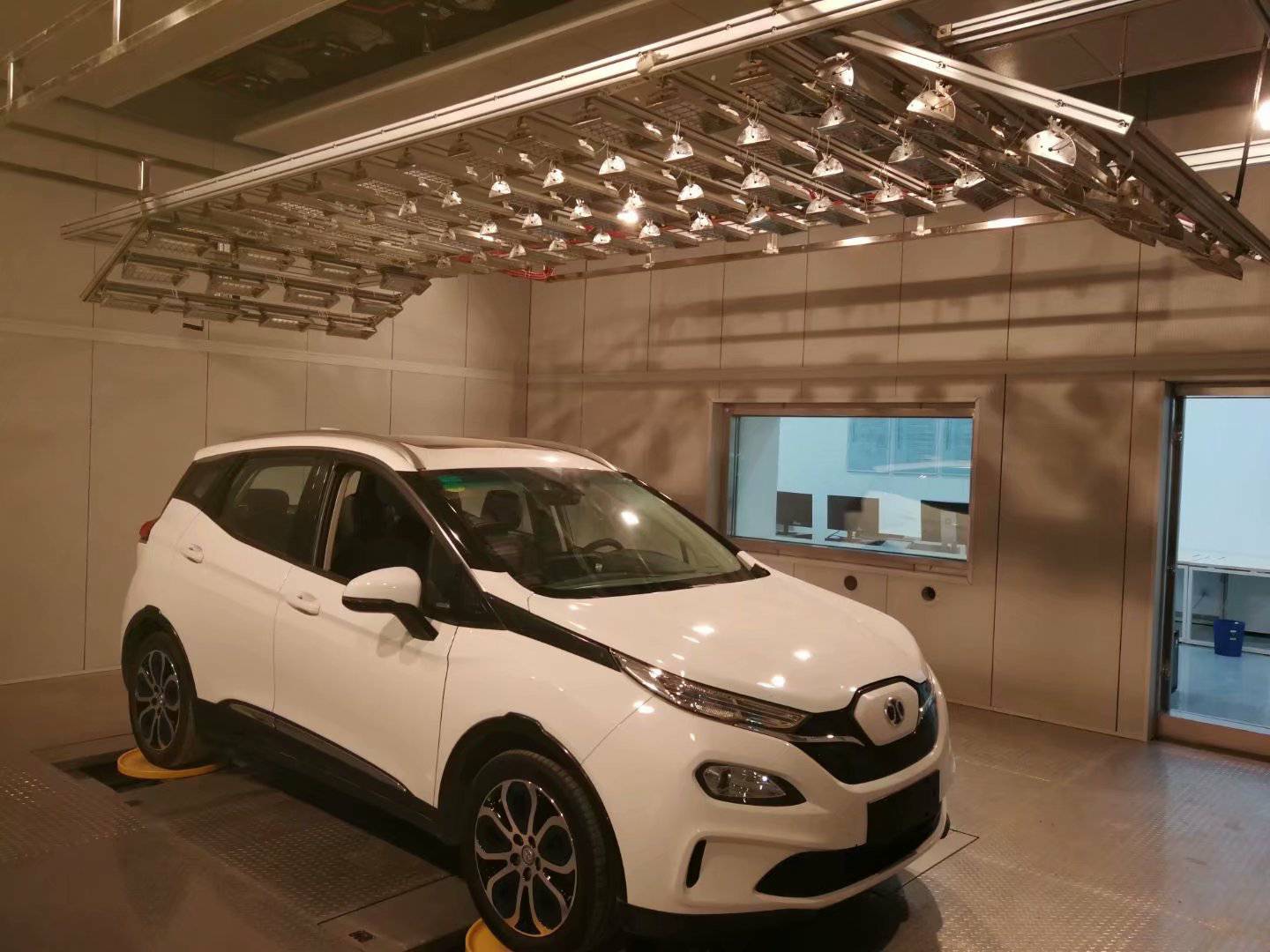

科技领先

公司产品已广泛应用于汽车制造、航空航天、军工制造、电子通讯、医药化工、检测计量、科研院校、电子电池等众多领域;同时也致力于光电、光伏、太阳能等新能源行业

品质保证

公司在强大的制冷与气候模拟技术力量的基础上,融合了前沿的环境箱控制技术与质量管理流程;竭诚为客户提供可靠,节能,性能优异的环测产品

优质售后

依靠现代化管理模式,秉承“团结协体,求实守信,积极进取,追求卓越”的精神,为客户提供各种环境试验设备和优良服务,产品在中外用户中得到了广泛的好评和信赖

解决方案

依靠现代化管理模式,秉承“团结协体,求实守信,积极进取,追求卓越”的精神

为客户提供各种环境试验设备和优良服务,产品在中外用户中得到了广泛的好评和信赖

新闻资讯

依靠现代化管理模式,秉承“团结协体,求实守信,积极进取,追求卓越”的精神,为客户提供各种环境试验设备和优良服务,产品在中外用户中得到了广泛的好评和信赖

电话:

电话:

邮箱:

邮箱:

2021 / 10-12

2021 / 10-12